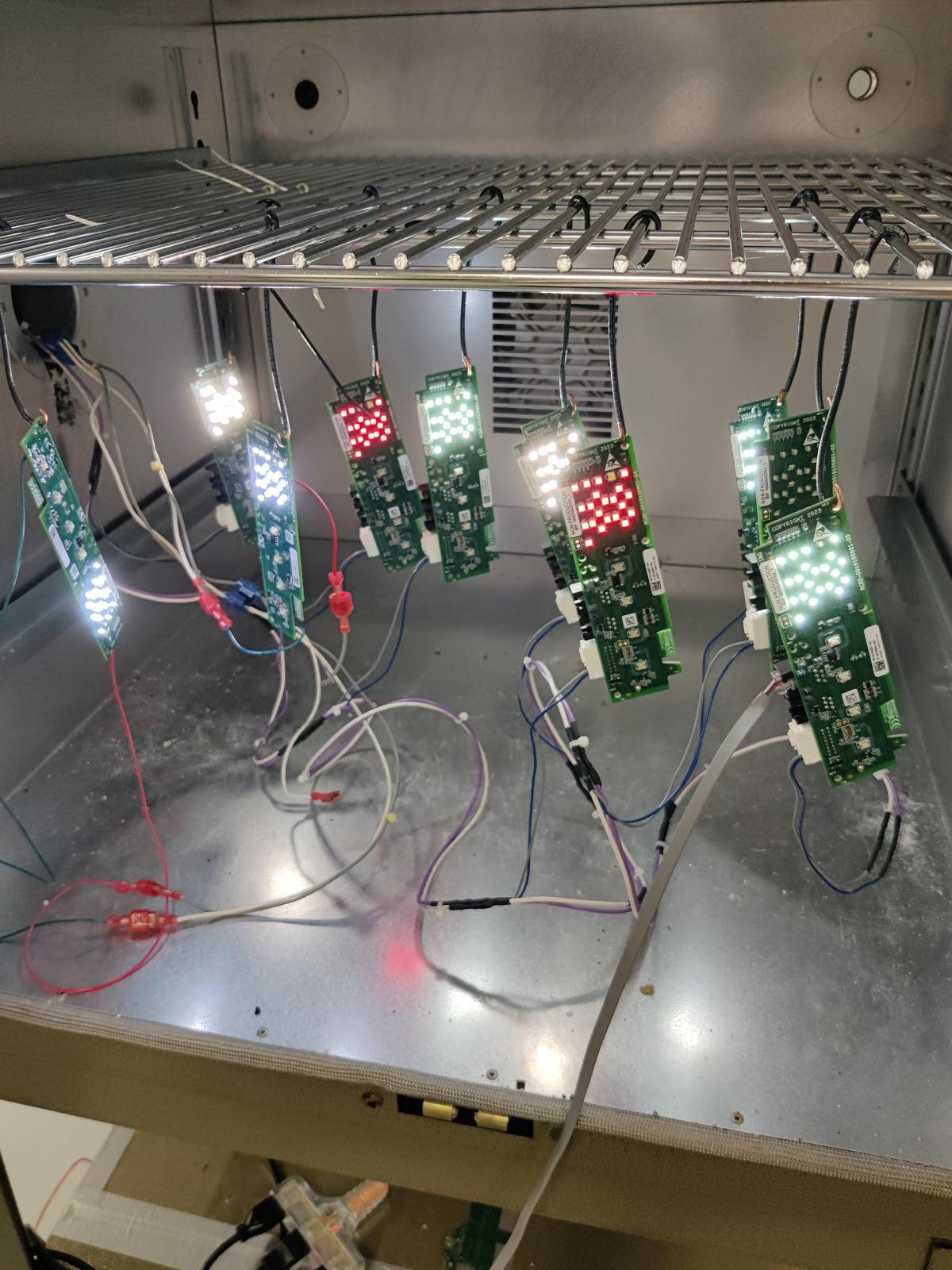

Hardware Validation & Integration

Hardware Validation & Integration Internship Project

Project Overview

During my first hardware internship at Rheem Manufacturing, I collaborated with test engineers to design, construct, and integrate PCB test fixtures. This project provided me with hands-on experience in hardware validation, failure diagnostics, and component qualification processes.

Key Responsibilities

- Collaborated with test engineers to design PCB test fixtures

- Constructed and integrated hardware test fixtures

- Supported electrical validation processes

- Performed failure diagnostics and root cause analysis

- Conducted component qualification testing

- Developed and released engineering specifications

- Created detailed schematics and documentation

- Prepared qualification documents for compliance

- Facilitated cross-team integration and knowledge transfer

Technical Achievements

- Designed robust PCB test fixtures that improved testing efficiency

- Developed comprehensive failure diagnostic procedures

- Created detailed engineering documentation and specifications

- Ensured compliance with industry standards and regulations

- Streamlined component qualification processes

- Improved cross-team collaboration and knowledge sharing

Technologies Used

Project Gallery

Confidentiality Notice

Note: This project was completed as part of my internship with Rheem Manufacturing. Due to confidentiality agreements and proprietary nature of the work, I am unable to share the source code or detailed technical specifications. The information provided here represents the general scope and impact of my contributions to the project.